Stability of perovskite solar cells reaches next milestone

With an improved material structure, a team from HZB achieves efficiencies of up to 24.6%

Perovskite semiconductors promise highly efficient and low-cost solar cells. However, the semi-organic material is very sensitive to temperature differences, which can quickly lead to fatigue damage in normal outdoor use. Adding a dipolar polymer compound to the precursor perovskite solution helps to counteract this. This has now been shown in a study published in the journal Science by an international team led by Antonio Abate, HZB. The solar cells produced in this way achieve efficiencies of well above 24 %, which hardly drop under rapid temperature fluctuations between -60 and +80 Celsius over one hundred cycles. That corresponds to about one year of outdoor use.

The material class of halide perovskites is seen as a great hope for even more solar power at even lower costs. The materials are very cheap, can be processed into thin films with minimal energy input and achieve already efficiencies that are significantly higher than those of conventional silicon solar cells.

The Goal: 20 Years Outdoor Stability

However, solar modules are expected to provide stable output for at least 20 years in outdoor conditions while exposed to large temperature fluctuations. Silicon PV manages this easily, whereas the semi-organic perovskites lose performance rather fast. "Sunlight can heat up the inside of a PV cell to 80 Celsius; in the dark, the cell then cools down immediately to the outside temperature. This triggers large mechanical stresses in the thin layer of perovskite microcrystals, creating defects and even local phase transitions, so that the thin film loses its quality," explains Prof. Antonio Abate, who heads a large group at HZB.

Chemical Variations examined

Together with his team and a number of international partners, he has investigated a chemical variation that significantly improves the stability of the perovskite thin film in different solar cell architectures, among them the p-i-n architecture, which normally is a little less efficient than the more often used n-i-p architecture.

A "Soft Shell" against Stress

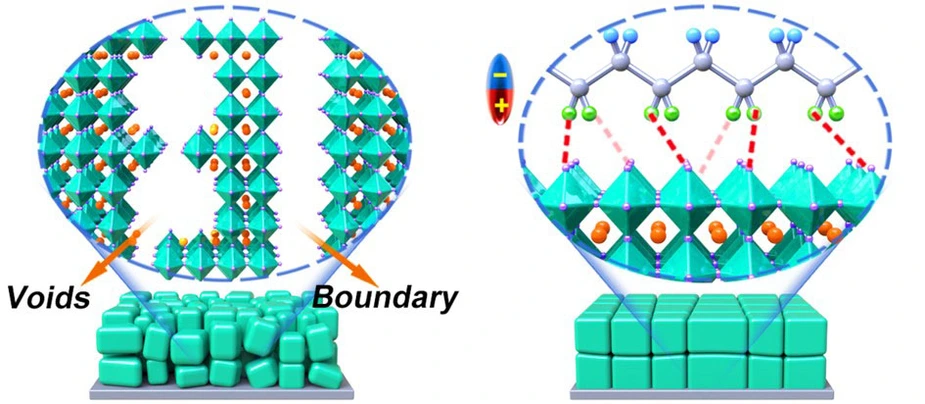

"We optimized the device structure and process parameters, building upon previous results, and finally could achieve a decisive improvement with b-poly(1,1-difluoroethylene) or b-pV2F for short," says Guixiang Li, who is doing his PhD supervised by Prof. Abate. b-pV2F molecules resemble a zigzag chain occupied by alternating dipoles. "This polymer seems to wrap around the individual perovskite microcrystals in the thin film like a soft shell, creating a kind of cushion against thermomechanical stress," Abate explains.

Record Efficiency for p-i-n Architecture 24,6%

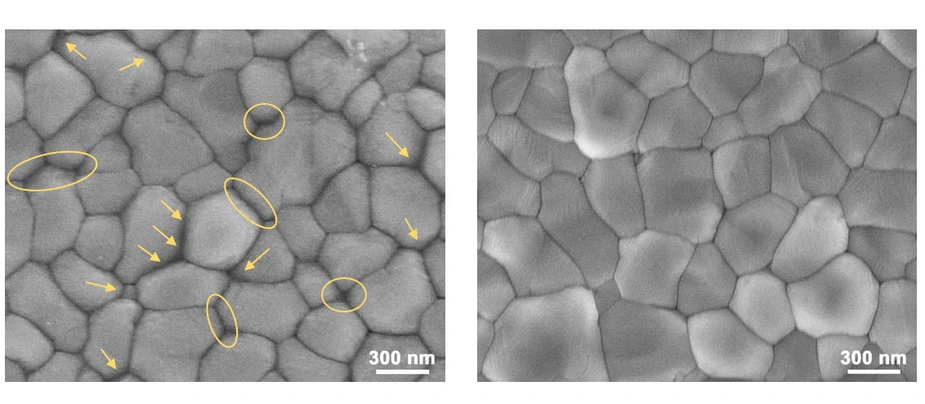

In fact, scanning electron microscope images show that in the cells with b-pV2F, the tiny granules nestle a little closer. "In addition, the dipole chain of b-pV2F improves the transport of charge carriers and thus increases the efficiency of the cell," says Abate. Indeed they produced cells on a laboratory scale with efficiencies of up to 24.6%, which is a record for the p-i-n architecture.

One Year Outdoor Use

The newly produced solar cells were subjected over a hundred cycles between +80 Celsius and -60 Celsius and 1000 hours of continuous 1-sun equivalent illumination. That corresponds to about one year of outdoor use. "Even under these extreme stresses, they still achieved 96 % efficiency in the end," Abate emphasises. That is already in the right order of magnitude. If it is now feasible to reduce the losses a little further, perovskite solar modules could still produce most of their original output after 20 years - this goal is now coming within reach.

Publication:

Science (2023): Highly efficient p-i-n perovskite solar cells that endure temperature variations

Guixiang Li, Zhenhuang Su, Laura Canil, Declan Hughes, Mahmoud H. Aldamasy, Janardan Dagar, Sergei Trofimov, Luyao Wang, Weiwei Zuo, José J. Jerónimo-Rendon, Mahdi Malekshahi Byranvand, Chenyue Wang, Rui Zhu, Zuhong Zhang, Feng Yang, Giuseppe Nasti, Boris Naydenov, Wing C. Tsoi, Zhe Li, Xingyu Gao, Zhaokui Wang, Yu Jia, Eva Unger, Michael Saliba, Meng Li, Antonio Abate

DOI: 10.1126/science.add7331

Contact:

Helmholtz-Zentrum Berlin für Materialien und Energie

Department Novel Materials and interfaces for photovoltaic solar cells

Albert-Einstein-Straße 16, 12489 Berlin

Guixiang Li

Phone +49 30 8062-17209

Email guixiang.li(at)helmholtz-berlin.de

Prof. Dr. Antonio Abate

Phone +49 30 8062-14380

Email antonio.abate(at)helmholtz-berlin.de

Press release HZB, 27 January 2023