Filming microscopic and macroscopic changes within materials

The EDDI beamline at BESSY II is now offering even more options

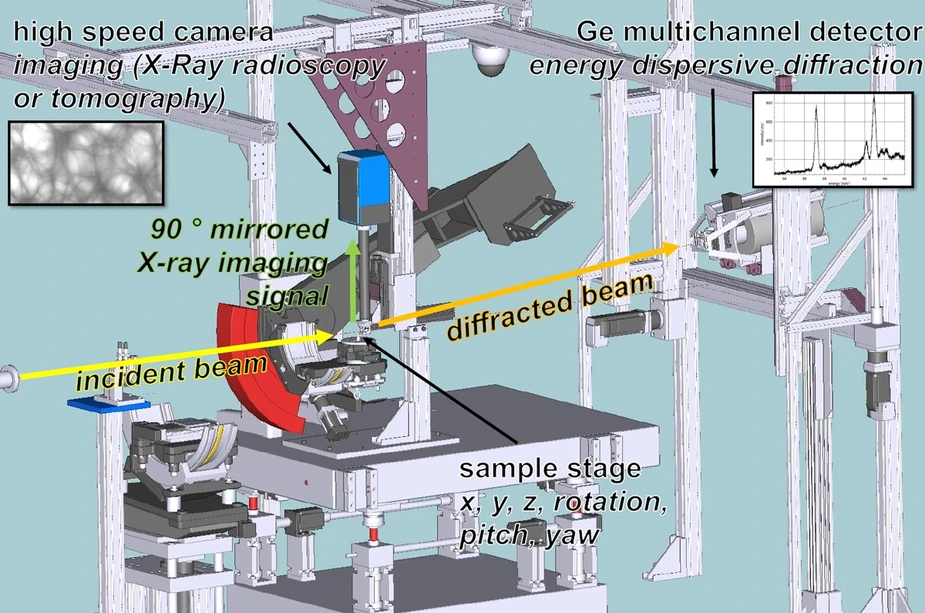

It has recently become possible to also obtain high-resolution three-dimensional images of microscopic structure with it, up to four such tomographies per second are possible. X-ray diffraction (energy-dispersive diffraction) can simultaneously be carried out to draw conclusions about the crystal structure of the material just as before.

Dr. Catalina Jiménez and Dr. Francisco García-Moreno, in charge of this option at the beamline, suggested this innovation in late 2013 and have now successfully implemented it. EDDI uses the complete energy spectrum of BESSY II X-ray pulses to rapidly create diffraction images that provide insight about the lattice structure and separation of atoms in the sample.

Constructing the sensor head

However, some of the X-rays travel unobstructed through the sample without being diffracted. This beam can now be transformed by a scintillator crystal into visible light and recorded by a camera. By rotating the sample, you obtain three-dimensional images in a process called tomography.

Realising this was not trivial. The sensor head with the scintillator crystal had to be situated close to the sample without hindering the path of the diffracted beam. “We worked closely on this with the HZB workshop”, García-Moreno reports.

Observing processes in energy materials

The sample table can be rotated and is equipped with sliding electrical contacts so that batteries can be investigated during their charging process, for example. There are also various ways to heat or cool the sample while measurements are being taken. “For example, we can observe changes that take place in batteries while charging, how hydrogen becomes deposited in steel, as well as investigating many other questions to do with energy materials”, explains Jiménez.

Up to four tomographic images per second

In the mean time, the team has demonstrated that the performance is even higher than expected. “We originally assumed that one complete tomographic image of a sample would take several seconds. But now we are even managing to do a diffraction spectrum simultaneously with up to one complete tomographic image per second, or up to four tomographic images per second by themselves. That means we can observe and film rapid changes in samples and correlate them with the corresponding phases in the material,” says García-Moreno. This feature has already been brought online in user operations and the first user groups with interesting proposals have already applied for beam time.

More information:

Dr. Francisco Garcia-Moreno

Institute Applied Materials

Tel.: (030) 8062-42761

Fax: (030) 8062-43059

E-Mail: garcia-moreno(at)helmholtz-berlin.de